Finite Element Analysis

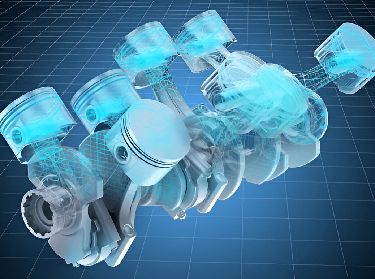

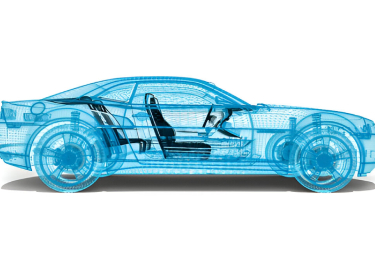

Finite Element Analysis (FEA) has become a highly beneficial technique in the field of computer-aided engineering & design, in particular for the modeling and analysis of structures with complicated geometries and non-linear material properties. It is now being widely used at the early stages of design within various engineering domains, including automotive, aerospace, power plants, production, and process industries, for product optimization that improves performance and reduces the cost of components.

Components that are subjected to thermal and structural loads can be evaluated with the FEA technique for structural reactions caused and their reliability under such load conditions without need to create the actual component.

FEA helps businesses accelerate the development of new products

in a very cost-effective manner with a shorter lead time,

thereby keeping them ahead of their competitors in the market.

The major cababilities of FEA are listed as follows:

Our team has extensive experience in finite element analysis of complex industrial products, automotive components that are exposed to different static, dynamic, thermal and impact loads. In response to these loads, hot spot regions are traced out and effective root cause analysis for the failure are cracked down, which is important to obtain an improved design.

We can also generate an innovative concept design proposal by using Topology, shape & Size, optimization techniques to obtain structure meeting all desired performance targets within a given package space. Thus, with FEA driven design development process, we could help our clients make decisions about product design during any stage of product development, cost efficiently.

LOOKING FOR HONEST AND RELIABLE SERVICES?

Best Engineering Partner For You

Connect Us With Our Online Form